Step 2 use your die grinder with a mounted point we like shape w222 and simply run the point over the edge of the sheet metal.

Folding sheet metal edge to eliminate sharpness.

Use a die grinder with the mounted point and simply run the point over the edge of the sheet metal.

This weakens the aluminium and creates a fracture line.

Secure the sheet metal to prevent slipping.

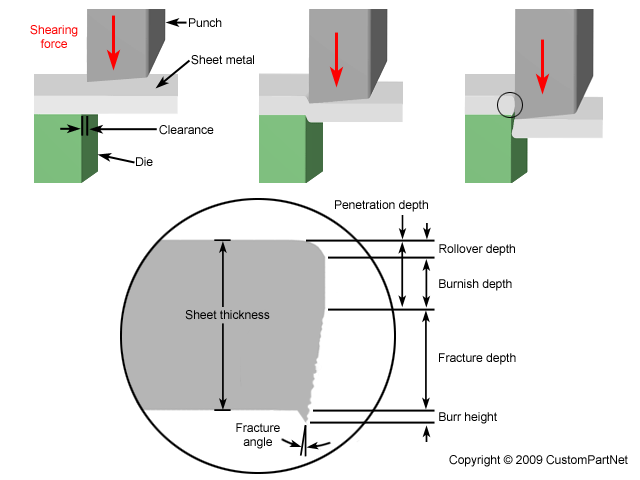

The edges may appear flat but shearing dies leave burrs.

Sheet aluminium can be cut without the need for a guillotine or tin snips which tend to deform the metal.

Run the point over the other sides to break those sharp edges.

This process will round the edge of the metal and create a groove in the point.

Edge bending is used to eliminate sharp edges.

As the groove in the point wears just move down the point to create a new groove and so on.

Figure 3 a sheared sheet metal edge has several attributes that make it sharp.

Place the fracture line over the edge of a table and bend the overhang slightly downwards.

Step 3 repeat.

Sheet metal s edges particularly with regard to the part after manufacture.

Many products use sheared sheet metal yet only one standard ul 1439 addresses the issue of sheet metal sharpness directly.

These sections are located at the edges.

With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet.

Edge bending operations are commonly used in industrial sheet metal processing and involve bending a section of the metal that is small relative to the part.

The edges may appear flat but shearing dies leave burrs.