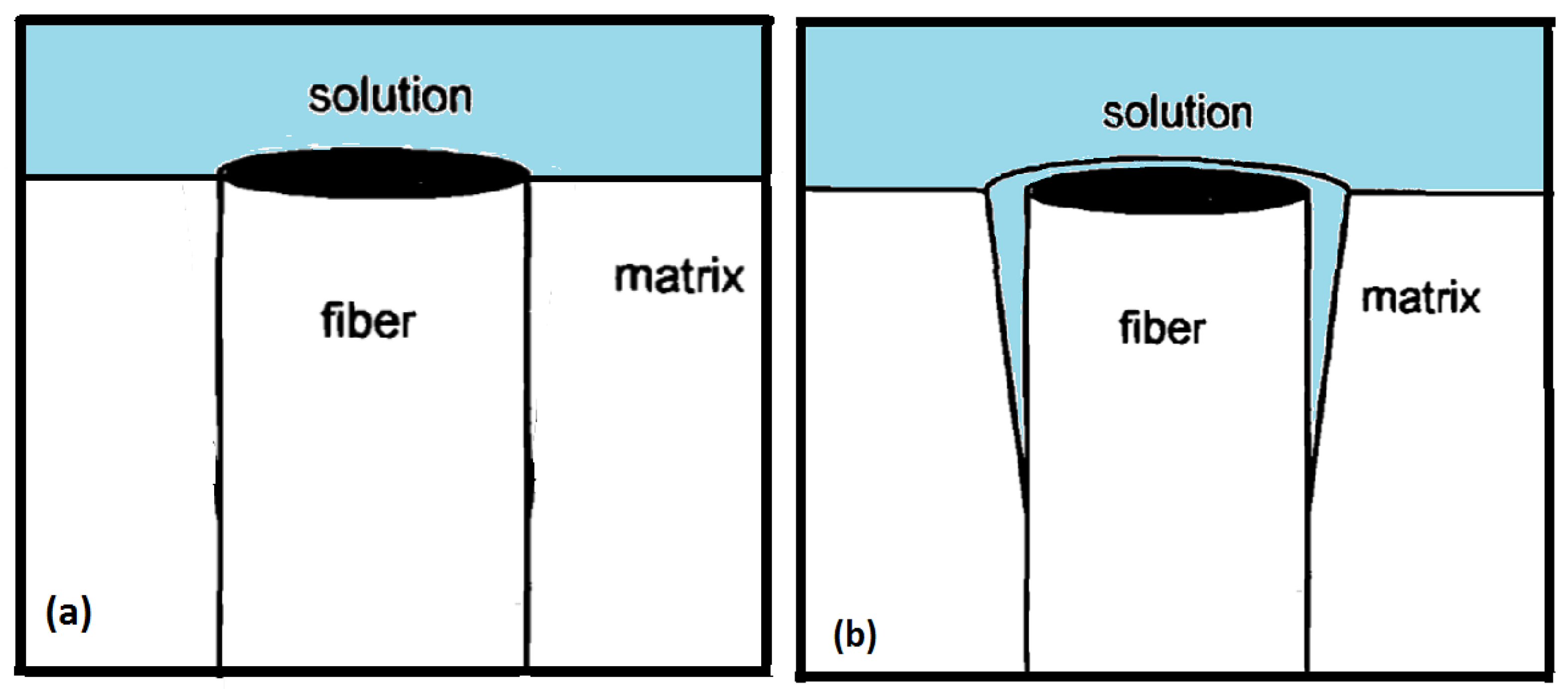

The matrix binds the fiber reinforcement transfers loads between fibers gives the composite component its net shape and determines its surface quality.

Fiber reinforced polymer vs ceramic.

The matrix can be some type of plastic also known as a polymer or it can be ceramic or metal.

This matrix is then strengthened and reinforced by the fiberglass or glass fibers.

Fiber reinforced ceramics are manufactured by infiltrating porous carbon fiber reinforced carbon components with liquid silicon.

Fibers forming spaces among the sic particles absorb the shock in increments so the phenomenon of instant cracking does not occur.

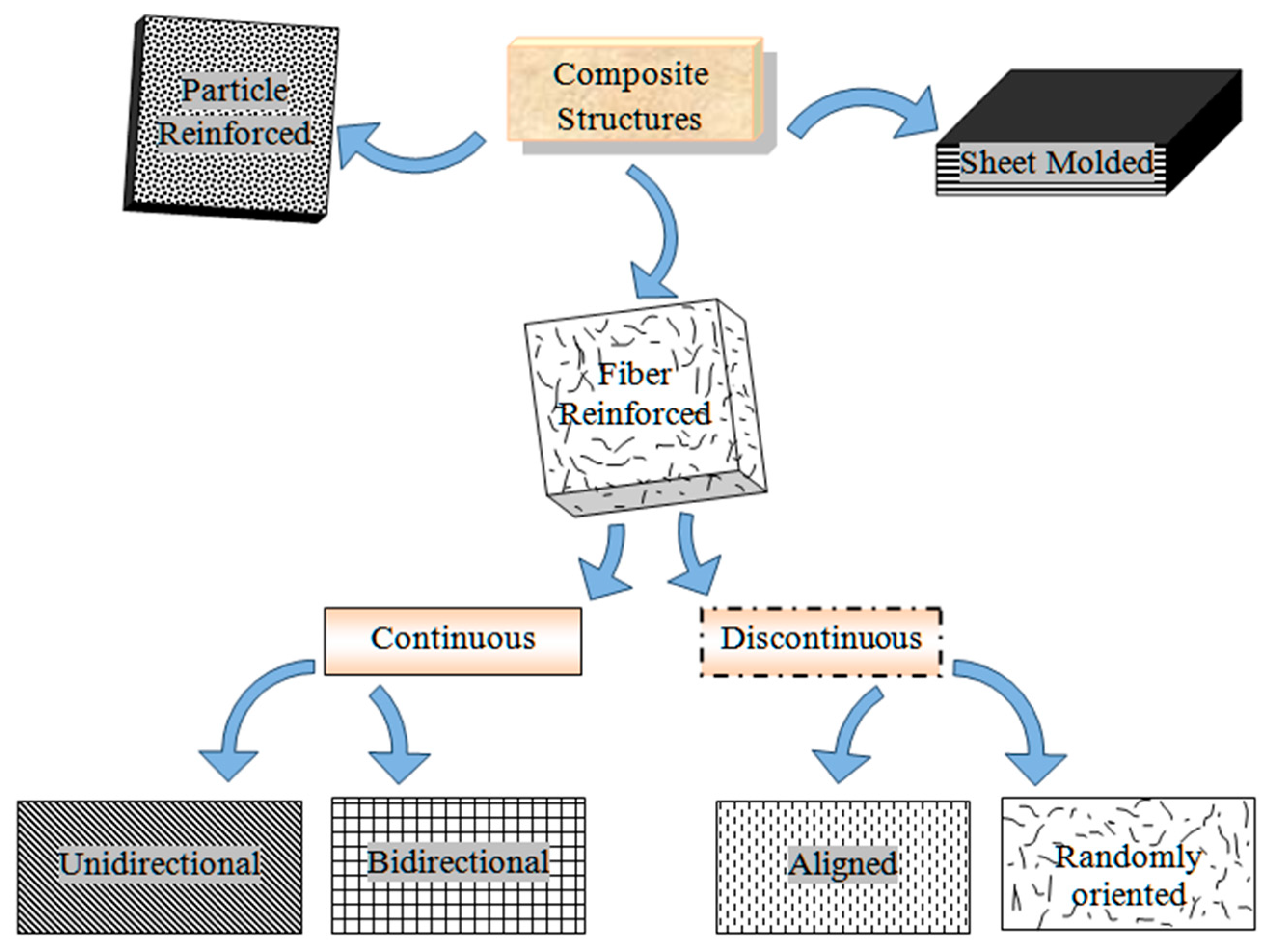

But the fibers can also be used in composite materials.

In ceramic materials cracks spread along grain boundaries in a linear manner.

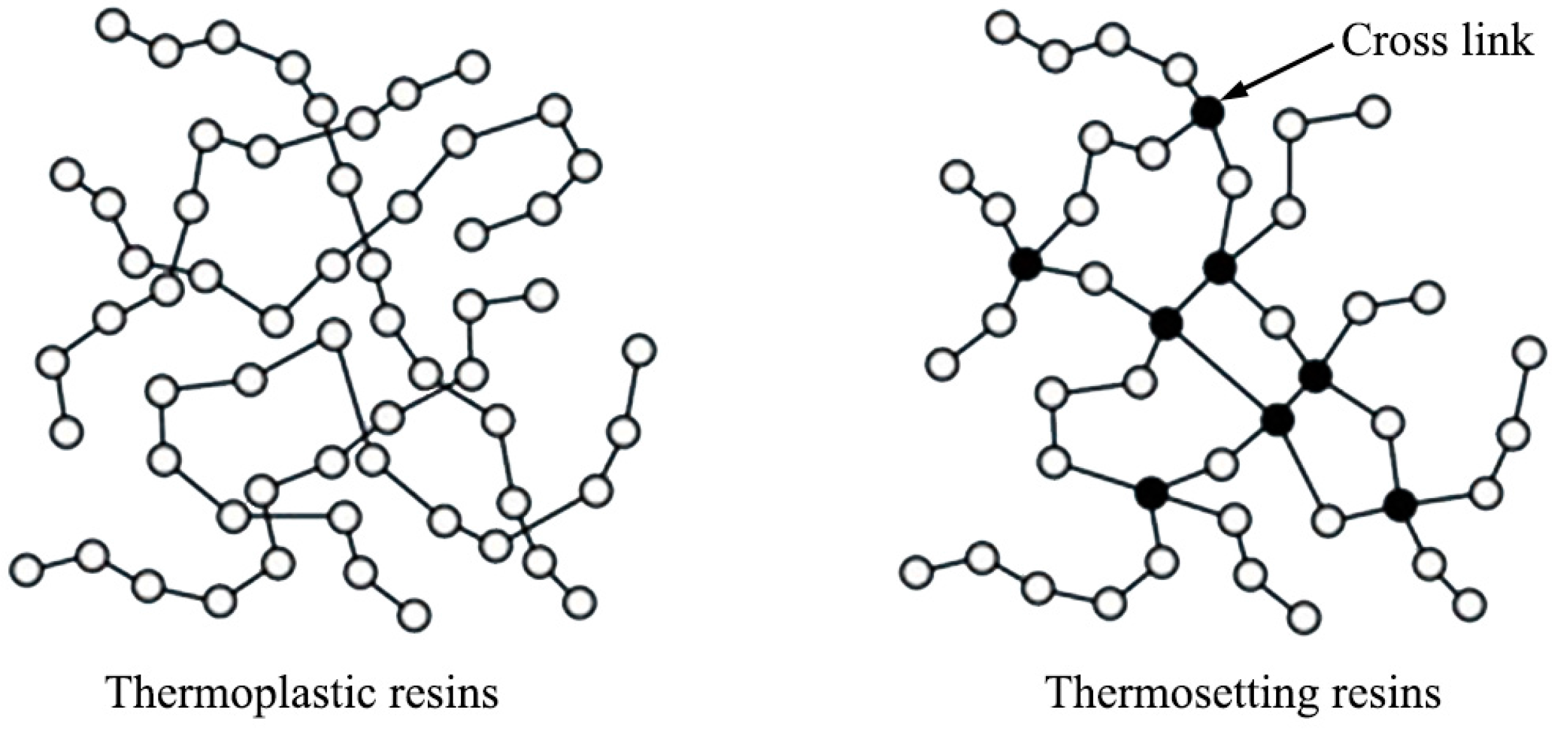

Polymer matrices are the most widely used for composites in commercial and high performance aerospace applications.

In the case of fiber reinforced composites cracks originating from shocks travel along the fibers thereby diffusing the impact.

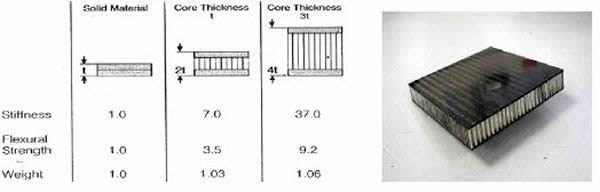

A composite is a mixture of materials often with a matrix and a reinforcement material.

A composite matrix may be a polymer ceramic metal or carbon.

The material properties can be customized to your application by the amount and type of carbon fibers milled fibers short or long fibers which are implemented into the ceramic sic matrix.

They can also be amorphous or have inhomogeneous chemical composition which develops upon pyrolysis of organic precursors the high process temperatures required for making cmcs preclude the use of organic metallic or glass fibers only fibers stable at temperatures above 1 000 c 1 800 f can be used.