Lens a small spot size lens less than 0 005 or 125 microns is the best for laser engraving and laser marking glass and ceramic materials.

Fiber laser marking ceramic materials.

Because they are composed of individual fibers the structural integrity can be damaged by the laser resulting in a blurry marking which cannot be scanned.

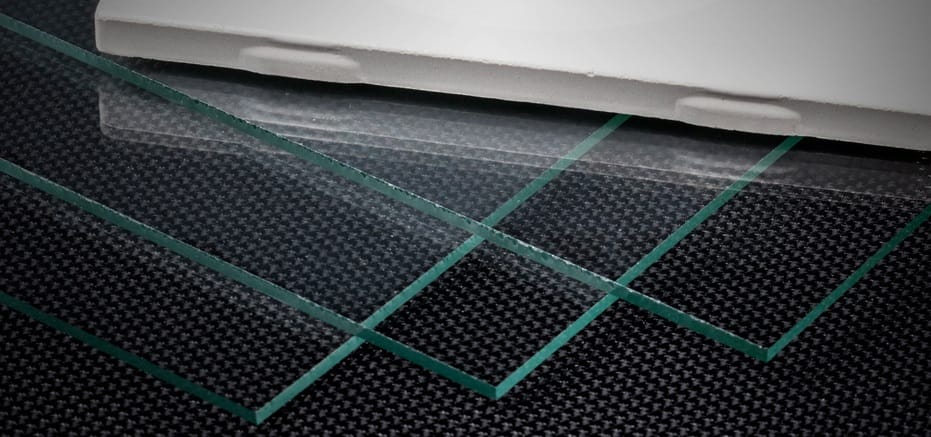

Laser cutting of thin film ceramic is also possible using a co 2 laser producing a clean edge with little discoloration.

Heatsign has perfected the art of ceramic marking using the most advanced laser marking technologies.

Laser marking is used on ceramic products for identification and traceability.

The following industrial lasers to profile drill scribe and imprint a range of business data including brand names logos graphics and 2d codes.

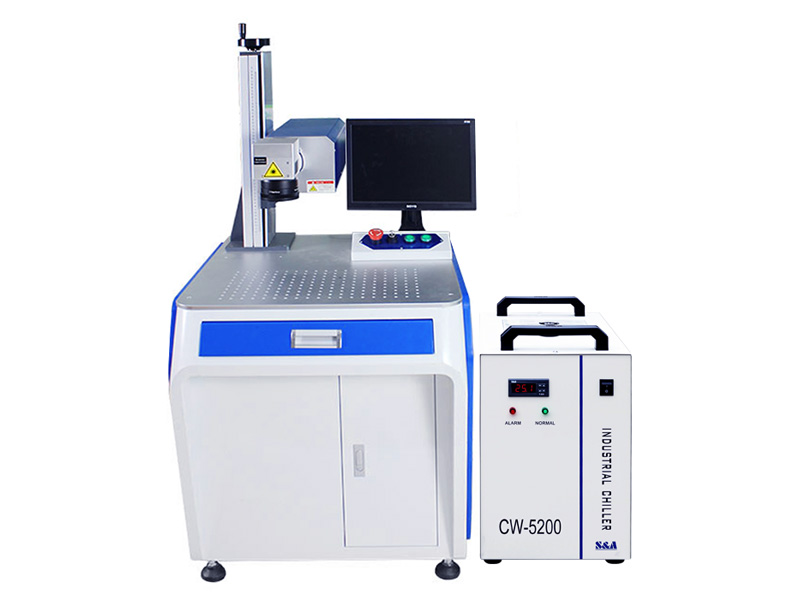

Laser processing of ceramics is typically performed using a 10 6 or 9 3 micron co 2 laser with some ceramics also absorbing a 1 06 micron fiber laser wavelength.

Typically we use 1064 nm fiber lasers for marking parts via melting.

Applications include part identification decorative marking and more.

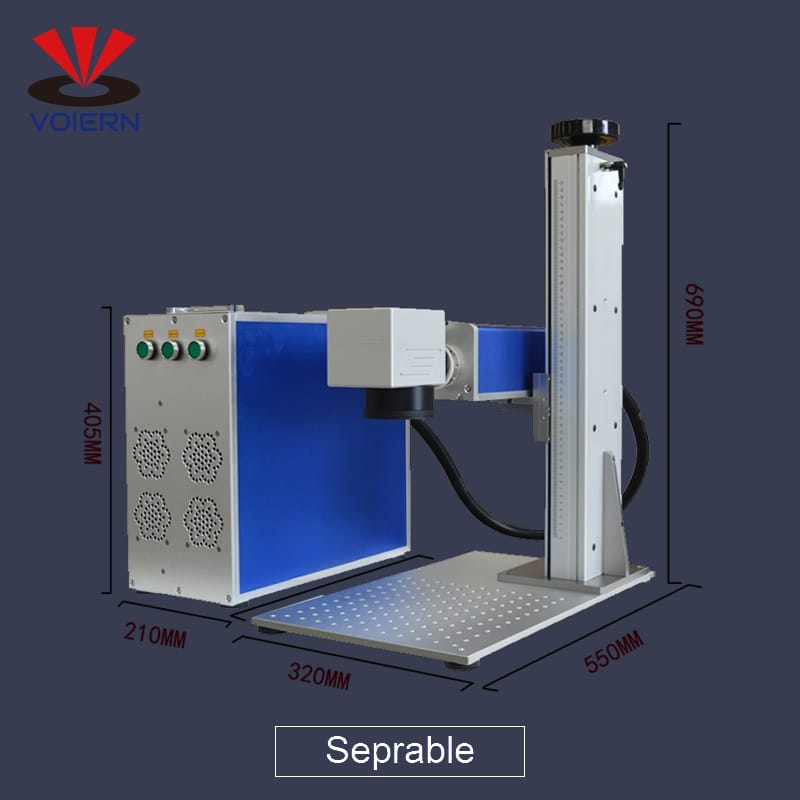

Fiber laser marking on organic insulating material a ceramic substrate ceramic package with han s laser mopa fiber laser technology.

The ccd vision system high accuracy x y moving table helps.

The laser s energy heats up the ceramic material melting the surface and causing a direct color change.